Garage Floor Coatings

They absolutely do! An uncoated garage floor is dirt’s best friend and if you’ve ever walked across one in your bare feet you probably know this all too well. The cracks, pits, chips and grooves in garages are the perfect place for dirt and debris to collect. We eliminate these areas by cleaning out the surface defects and then fill them prior to applying our custom coatings, leaving you with a beautiful, seamless floor.

Another function of having a professionally installed garage floor coating by Bach Custom Coatings centers on spills and/or leaks. Concrete by its very composition is porous and as a result allows such things as motor oil, transmission fluid, beverage spills, insecticide or pesticide spills or any other substance to penetrate the surface and become a permanent part of the slab.

Beyond the unsightliness of the stains, some of these chemicals can be extremely damaging to your concrete and potentially to the environment as well. Just as water can wick up through concrete, so can harmful chemicals, ultimately leading to groundwater pollution. By sealing the capillaries in the slab we provide you with a seamless floor that repels dirt and contaminates rather than allowing them to adhere or soak in.

It’s unlikely that you’ll need a garage floor coating that is protected from such things at bacteria or other micro-organisms, but that is another protective feature one of our custom concrete coatings provides. The same industrial grade products we use on garage floors are also found in restaurants and food processing facilities where strict USDA standards must be met. If you have children or pets that will be spending any time in the garage you can rest assured that they will have another level of protection under their feet.

Benefits to a Coated Garage Floor:

- Adds safety by incorporating a slip resistant finish

- Increases property value

- Extends the usable square footage of your home

- Creates a room you’re actually proud to spend time in

- Provides another safe area for children or pets to play during inclement weather

- Keeps your garage much easier to keep clean

We also believe education doesn’t stop with us. As a consumer, it’s equally important that you get the answers you’re looking for. We know an informed person will make far better choices than one who refuses to take the time to learn. With this in mind, we will encourage you to ask as many questions as you like and will do everything in our power to ensure you receive clear and understandable answers. In fact, we have a FAQ page to help you get started in this process.

At this point a friendly estimator will come out to your home and evaluate the condition of your garage floor. We’ll show you actual samples of our flooring systems and through your input, determine what color and style will best suit your needs. We’ll measure the floor and provide you with an accurate, low pressure, written quote.

The next step is to schedule the install of your new custom garage floor.

The Application Process for our “Granite Flake” system:

- We start the preparation process by diamond grinding. We will remove any existing paint, oil stains, sealers or other contaminants that would inhibit a proper bond between the concrete and the coating.

- Cracks, spalls, pits, and chips are cleaned out and filled with a rapid curing agent, then ground flush with the surrounding slab.

- All areas adjacent to the coatings application are protected with a detailed masking.

- At this point, your floor is now ready to receive the coating with the color you’ve selected. A pigmented base coat of either polyaspartic or epoxy (depending on moisture content in the slab) is put down followed by a full broadcast of multi-colored chips.

- Once cured, the surface is thoroughly scraped, sanded and vacuumed to remove the excess color chips.

- A clear protective polyaspartic topcoat is applied to give the floor a beautiful, long lasting shine.

- We inspect the finished floor with you and go over details such as when you can walk on and drive on your new floor. We will also go over care and maintenance with you at this point.

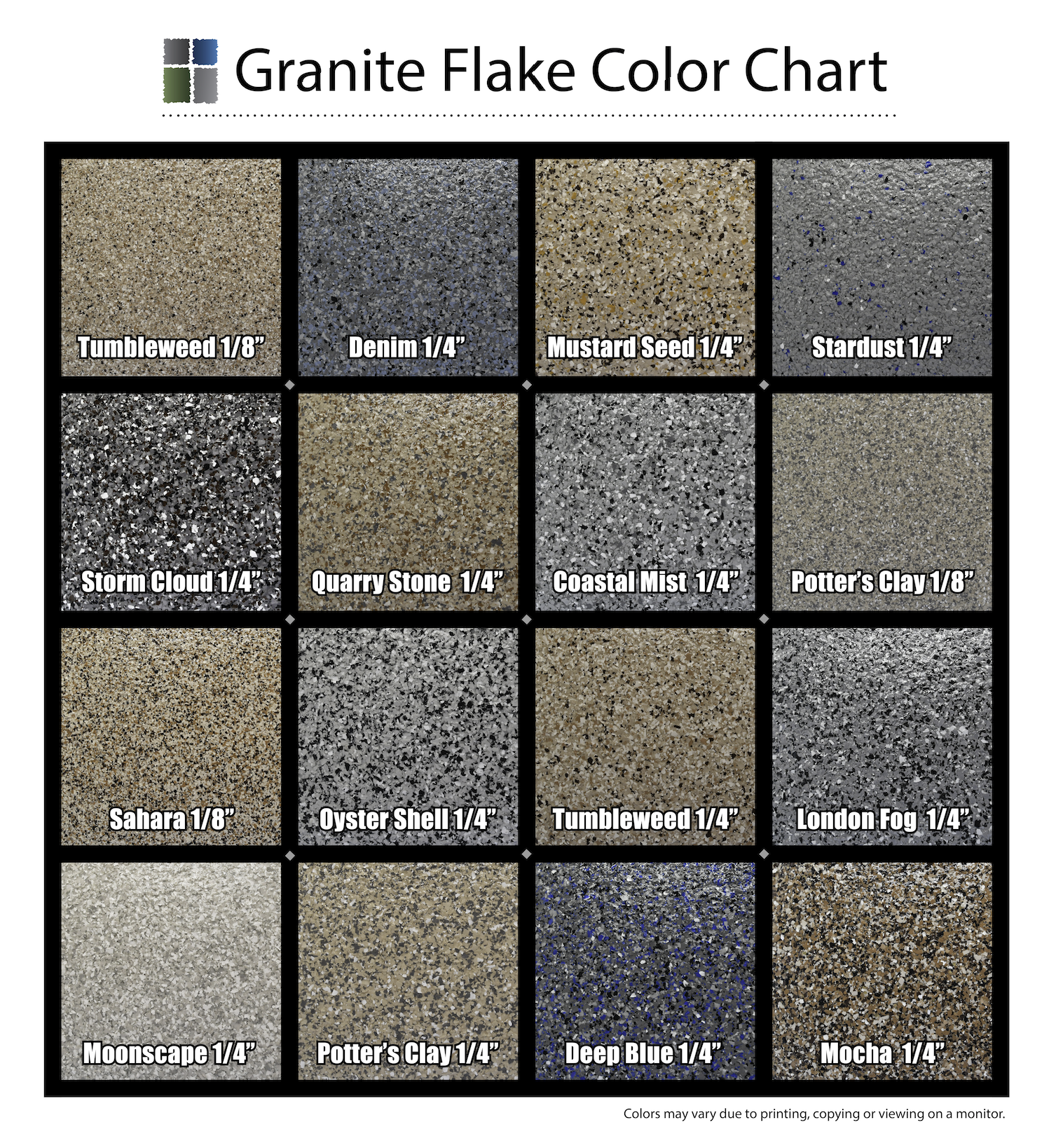

Standard color choices for our Granite Flake garage floor coating system